Sway Bar Manufacturing By Betts Spring

Betts Spring Manufacturing designs and manufactures sway bars that are precision-engineered for strength, resiliency, and durability.

Our sway bars are a product of precision engineering and years of expertise in the automotive, motorsports, and trucking industries.

Your customers and brand will benefit from quality sway bars designed and engineered by the premier manufacturer of automotive aftermarket and ATV/UTV components in the country.

The quality of the material and design guarantees a smooth transitional sway bar function, decreasing the feedback response time, and increased stiffness over stock parts.

Betts manufactures sway bars according to a wide variety of possible specifications, including:

- Sway Bar diameters from 5/8″ to 1-1/2″

- Bar material can be either solid or tubular.

- Material grades 1018, 1026, 5160, 9254, 4140, and 4340.

- Forged end sway bars, multiple hole end sway bars, or custom end sway bar configurations for all automotive aftermarket and UTV applications.

- Splined-end torsion bars

- Sandblasting, shot peening, logo imprint, heat treating, and powder coating production options.

The Sway Bar Manufacturing Process

Design Phase

-

- 3D CMM Scanning of samples

- CAD (Computer-Aided Design) software is used to draft and optimize the sway bar design.

- The design is optimized for the size of the vehicle and the number of bends.

Material Selection

-

- We only use high-strength, resilient materials that withstand the rigorous demands of automotive applications.

Manufacturing

-

-

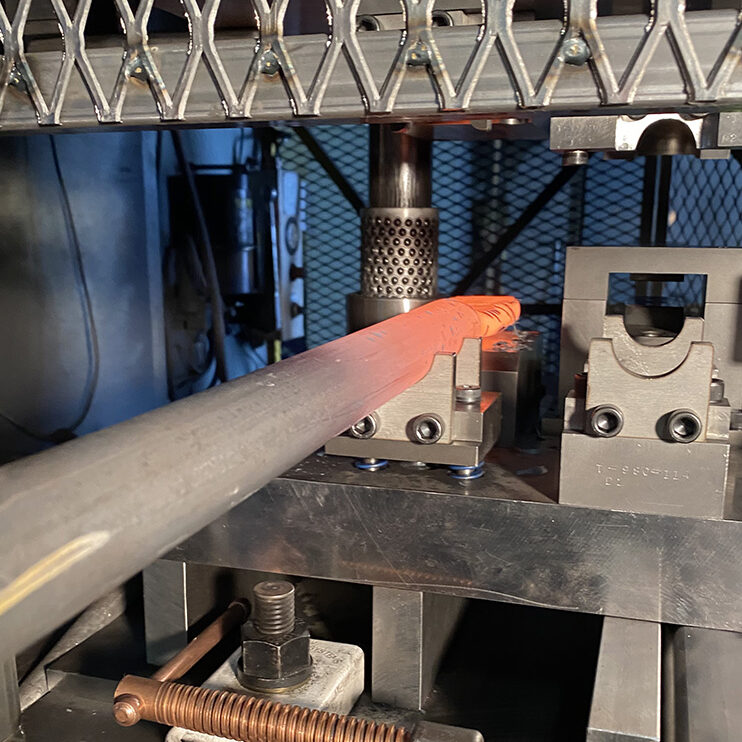

- The bar is cut to the proper length for the application and bent to the correct shape using CNC benders.

- Ends are manufactured by forging the stock material into shape. Alternatively, welded ends can be specified for more unique applications.

- Where needed sway bars are heat-treated or stress-relieved for improved durability.

-

Contact us today with your questions or to speak to our expert team about manufacturing sway bars to suit your custom application.

What Is a Sway Bar?

A sway bar, also known as an anti-roll bar, is a crucial component designed to reduce a vehicle’s body roll during cornering. It connects the suspension system of the vehicle on either side, maintaining equilibrium and enhancing stability and handling.

A sway bar is typically constructed out of a cylindrical steel bar that is heat-treated and bent on both sides. A sway bar is connected to a vehicle’s body at both ends and at two points along its center section.

The History of Sway Bars

Sway bars trace back to the early 20th century, with the first patent registered in 1919 by Canadian inventor Stephen Coleman. They have since evolved, becoming a standard feature in modern vehicles, providing a balance between ride comfort and handling performance. By connecting the left and right suspension systems, sway bars distribute the forces experienced during cornering, ensuring a smoother and more controlled ride.

Sway Bars in Modern Applications

In the dynamic world of automotive performance, sway bars play a pivotal role in ensuring vehicles remain stable and grounded, especially during sharp turns or uneven terrain. Our sway bars are crafted to provide that extra edge in performance.