A Legacy of Spring Manufacturing Since 1868

Betts Spring Manufacturing, a division of Betts Company, has been solving spring engineering challenges since 1868. We’re the first spring manufacturer in the Western United States and the oldest spring manufacturer west of the Mississippi River.

We have been family owned for six generations, Building Well, Serving Better® Since 1868.

As your single source for custom springs, sway bars, and torsion bars, we handle everything under one roof at our Fresno, California facility. When you work with Betts Spring Manufacturing, you work with one team, one facility, and one point of accountability for your custom spring, sway bar, and torsion bar applications.

Who We Work With

We work with design engineers, product developers, and OEM manufacturers across North America who need a reliable custom spring manufacturer for demanding applications.

We serve customers in a wide range of industries, including:

If your application requires precision-engineered springs to improve the way your products move and perform, we’re your one-stop source.

Custom Spring Materials

We manufacture springs from comprehensive materials including chrome silicon alloy steels (SAE 5160H, SAE 9254), stainless grades (SAE 302/304/316, 17-7 PH), music wire (ASTM A228), chrome vanadium (ASTM A231), and oil tempered steels (ASTM A229).

Be sure to visit our materials page for complete materials specifications and heat treatment capabilities.

Custom Spring Manufacturing

Looking for a proprietary spring design for your custom application? Our dedicated spring engineering team works directly with you. Our collaborative design process is straightforward: we review your details, communicate on missing specifications, and produce cost estimates with preliminary designs.

Looking for a proprietary spring design for your custom application? Our dedicated spring engineering team works directly with you. Our collaborative design process is straightforward: we review your details, communicate on missing specifications, and produce cost estimates with preliminary designs.

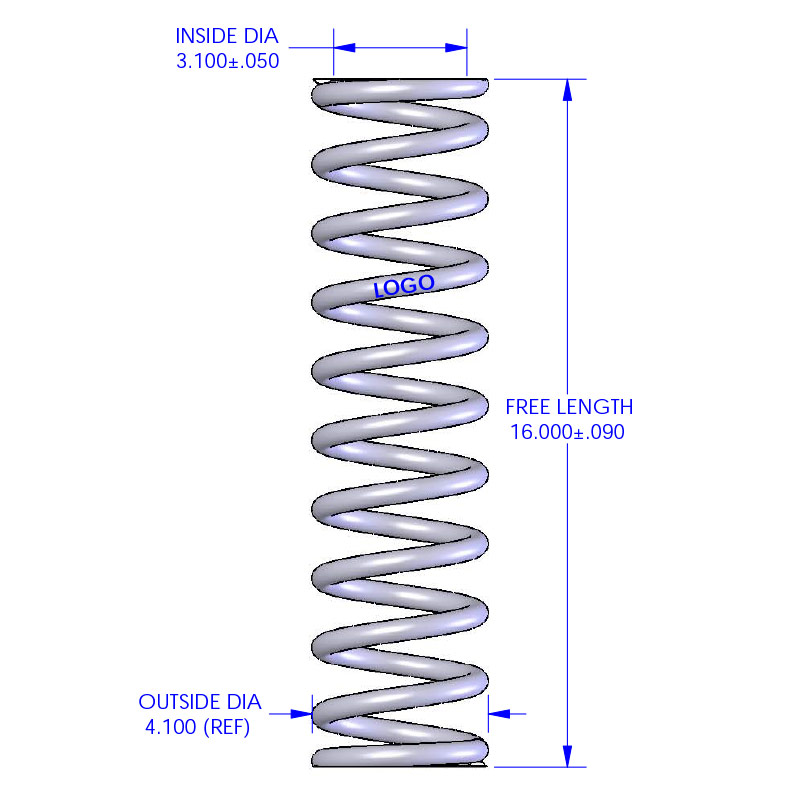

We manufacture compression springs for load bearing applications, extension springs for tension applications, and torsion springs to withstand rotational force. Each spring is engineered with proper stress analysis, material selection, and manufacturing controls for reliable performance. This includes specialized designs like dual rate and side load springs when your application requires variable spring rates or off-axis loading conditions.

Our process scales from First Article production samples through high-volume manufacturing using the same tooling and quality standards. We maintain greater than 95% on-time delivery with lead times better than industry average.

Hot Wound Spring Manufacturing

We manufacture hot wound coil springs from bar stock ranging from .500″ to 1.750″ diameter for mining equipment, construction machinery, commercial truck suspensions, and industrial applications where failure isn’t an option. Our fully automated continuous flow line processes over 125 tons of steel per month.

Cold Wound Spring Manufacturing

Our CNC coiling machines produce cold wound compression, extension, and torsion springs from wire diameters ranging from .095″ to .640″ for automotive components, industrial machinery, medical devices, and performance applications. Precision tolerances ensure your springs assemble correctly every time.

Leaf Spring Manufacturing

We manufacture single-leaf and multi-leaf spring assemblies for commercial trucks, military vehicles, agricultural equipment, and specialty applications where reliability under load is non-negotiable. Each leaf spring starts with certified spring steel, heat treated for optimal strength and flexibility.

Custom Sway Bar Manufacturing

We manufacture sway bars from 0.625″ to 1.5″ bar diameter in solid or tube construction. Our sway bars are precision-engineered components that directly impact vehicle handling, stability, and safety for automotive, motorsports, and commercial trucking applications.

For detailed material specifications and technical capabilities, visit our sway bar manufacturing page.

Torsion Bar Manufacturing

We manufacture torsion bars from 0.625″ to 1.5″ diameter in solid bar or tube construction for military vehicle suspensions, specialty industrial equipment, and applications demanding reliable performance in challenging environments.

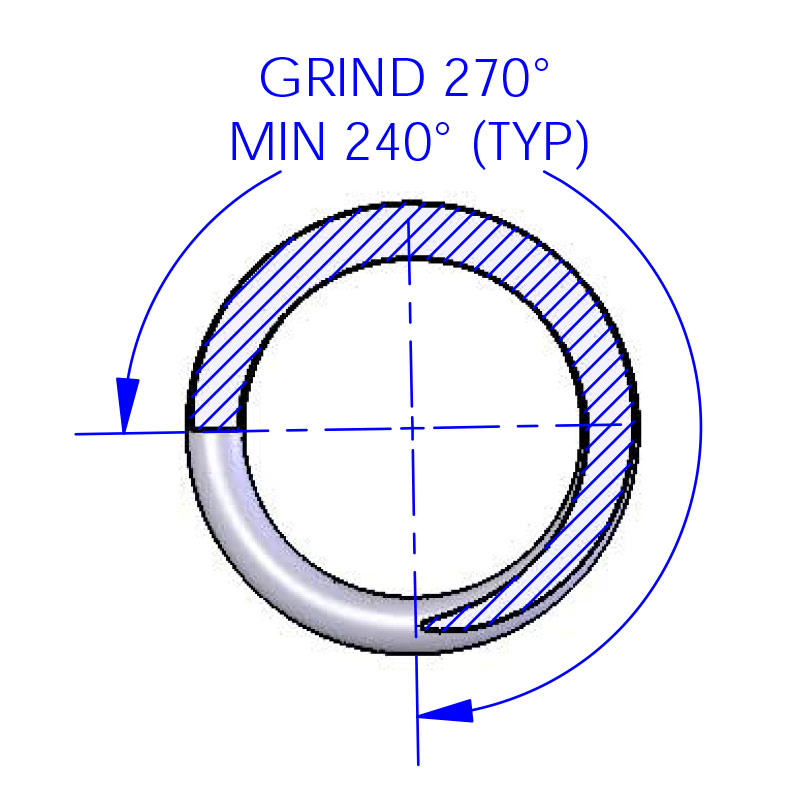

Shot Peening, Powder Coating, Custom Logos

All finishing processes happen in our Fresno facility. Shot peening induces beneficial compressive residual stresses in the surface layer, significantly improving resistance to fatigue crack initiation and extending service life in high-cycle applications. Our state-of-the-art powder coating system features the largest conveyorized ovens and purest wash system in the industry, delivering superior finish durability in any color or specification you require. Stress relieving for dimensional stability.

We also offer custom logo packaging for companies requiring branded components. Having these secondary operations under one roof eliminates coordination with separate vendors and ensures consistent quality

Why Engineers Choose Betts Spring

When you’re evaluating spring suppliers, you’re making a decision that affects product quality, launch schedules, and your credibility.

Dependable Spring and Sway Bar Engineering

Your customers depend on you to specify the right components. Our spring engineering team works with you to optimize designs, select appropriate materials, and identify potential issues before they become expensive failures. We’ve helped hundreds of engineers with solutions for challenging applications.

We review your application requirements, load specifications, operating environment, and space constraints. Our team uses this information to develop preliminary spring designs and material recommendations. This collaborative approach means fewer prototype iterations, faster time to production, and springs that perform reliably in service.

We don’t just manufacture what you specify. We make sure what you’re specifying will work. Our engineers have solved spring design challenges across mining, construction, military, agriculture, and industrial applications. When you call with a technical question, you talk directly with manufacturing professionals who understand springs.

Spring Manufacturing Quality You Can Depend On

We’re ISO 9001:2015 certified with full process documentation and traceability. But certification is baseline. What matters is that we’ve built quality into our processes since our founding in 1868.

Our testing capabilities include load testing up to 50,000 pounds, metallurgical analysis, magnetic particle inspection, hardness testing, and 3D CMM verification. First Article production sample testing validates new designs before full production begins.

We maintain complete records for every component: manufacturing date, material heat lot, process parameters, and inspection results.

Quality isn’t a department at Betts Spring. It’s how we manufacture. Our process controls catch variations before they become out-of-spec parts. Material certifications verify you’re getting the specified alloy and heat treatment.

For customers requiring additional quality documentation, we provide material certifications, lot traceability, and process verification. Medical device and aerospace customers receive the full documentation their industries demand.

Spring Manufacturing Under One Roof

Design, engineering, manufacturing, heat treatment, shot peening, powder coating, testing, and custom packaging all happen in our Fresno facility. You work with one team who owns the entire process. When you call with a question or need to modify specifications, you talk to people who know your project.

This integration speeds everything up. Design changes don’t require new vendor quotes and coordination. Prototype iterations happen faster because our engineers work directly with our manufacturing team. Production runs smoother because the people who designed the tooling work in the same building as the people running the machines.

We offer EDI-compatible electronic ordering systems for seamless integration with your operations. Our automated hot wound line and CNC cold winding equipment provide the capacity to handle both prototype quantities and full production volumes. We’re continually expanding our equipment capabilities to serve your evolving needs.

No coordinating between separate design firms, contract manufacturers, and finishing houses. No delays while information passes through multiple vendors. No confusion about who’s responsible when something needs to change. One facility. One team. One point of accountability.

On-Time Delivery

We maintain greater than 95% on-time delivery with lead times better than industry average. We communicate clearly about schedules, flag potential delays early, and do what’s required to meet your timeline. We are located in Fresno, California and have easy access to shipping routes throughout North America.

157 Years of Manufacturing Experience

Since 1868, we’ve been engineering and manufacturing springs. We’re the oldest spring manufacturer west of the Mississippi River because we’ve continuously adapted and improved. The Science Channel featured our manufacturing process on “How It’s Made” because what we do combines traditional craftsmanship with modern technology.

ISO 9001:2015 & ITAR Registered

ISO 9001:2015 certification demonstrates our commitment to quality management and process control. We’re also ITAR registered for defense and military applications requiring security clearances and controlled material handling.

Ready To Work With a Reliable Partner?

Contact our sales and engineering team today about your custom spring, sway bar, or torsion bar application or call us at 800-227-2192.

We’ll discuss your requirements, answer your technical questions, and determine if we’re the right partner for your needs.

Betts Spring Manufacturing, a proud division of Betts Company, has been your single source custom spring manufacturer since 1868. We’re still here because we deliver what we promise, when we promise it, built to the specifications that matter to you and your customers.

Building Well, Serving Better Since 1868